Per the NMSU Hazard Communication Program, all containers of hazardous chemicals in the workplace must be properly labeled. There is specific information that must be included on original (manufacturer) and on workplace (secondary) container labels.

Original Container Labeling

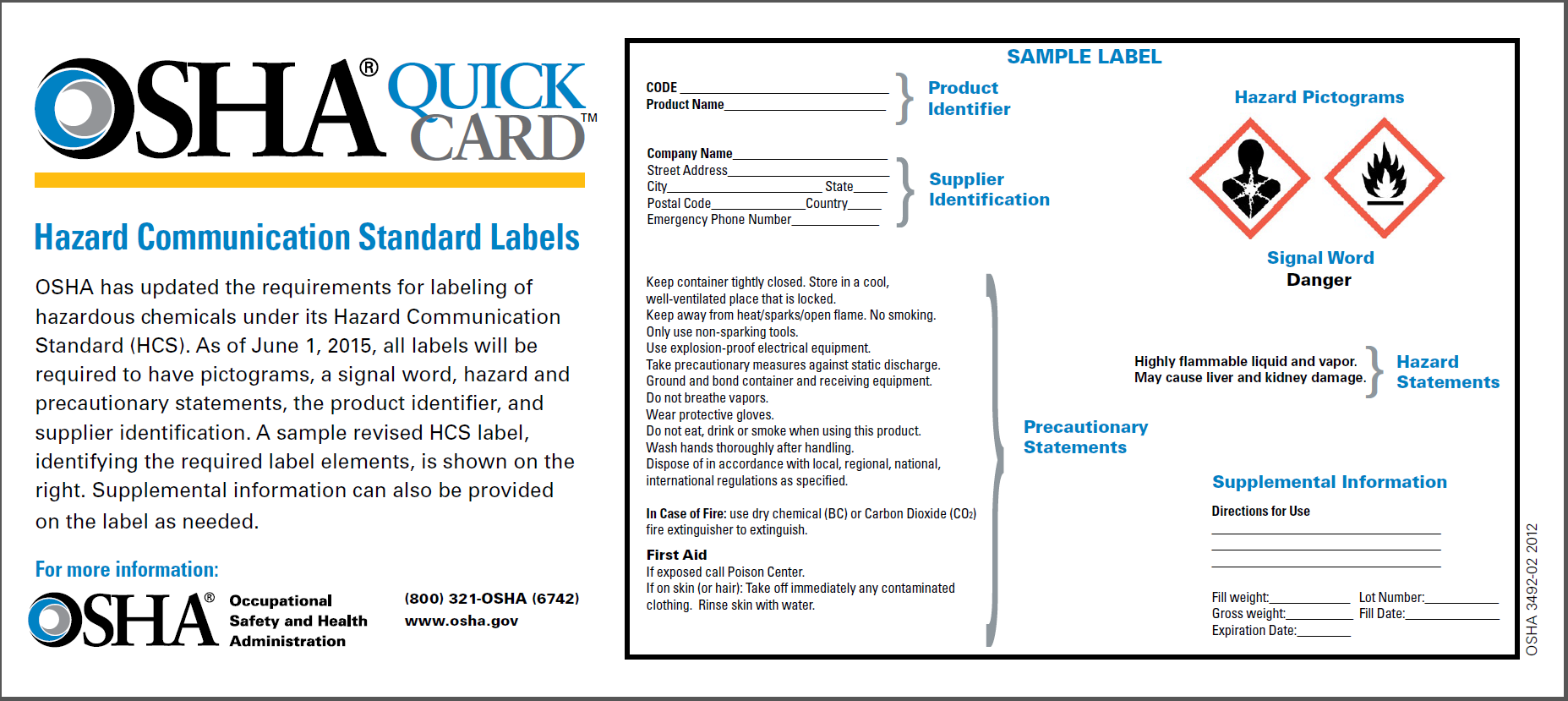

Under the new Globally Harmonized System of Classification and Labeling of Chemicals (GHS), all new containers shipped to NMSU will have labels with the following information:

The original manufacturer label must remain legible at all times. If the original label is damaged, removed or defaced the label must be replaced immediately with a new label containing the same information.

Workplace (Secondary) Container Labeling

During routine laboratory or shop operations, hazardous chemicals are frequently transferred from the original container into a secondary container. Unless it is intended for immediate use by the employee who performs the transfer, a workplace label is required on these secondary containers.

At a minimum, the workplace container label must include the following:

- Product identifier

- Specific information concerning the physical and health hazards of the chemical. The hazards may be identified by using words, pictures, symbols or a combination thereof.

EH&S recommends that workplace containers be labeled with the same information that is on the original manufacturer label (using all of the elements shown in the sample label above), or an alternate labeling system, such as NFPA.

In addition, workers must have quick access to the appropriate chemical Safety Data Sheets (SDS) which provide a complete description of the chemical constituents and detailed hazard information.

EH&S highly recommends using the National Fire Protection Association (NFPA) 704 labeling system for workplace labels.

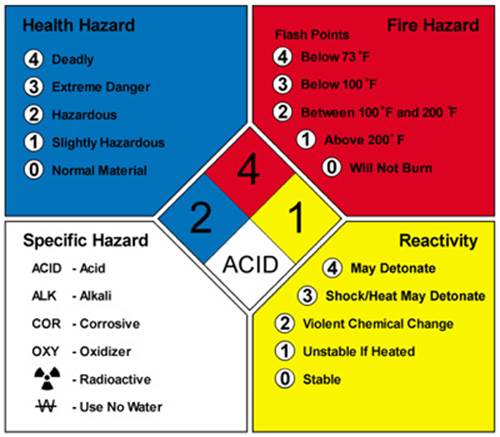

Summary of NFPA 704 Hazard Information System

The National Fire Protection Association (NFPA 704) system uses a diamond-shaped diagram of symbols and numbers to indicate the degree of hazard associated with a particular chemical or material. These diamond-shaped symbols are placed on containers of chemicals or materials to identify the degree of hazard associated with the chemical or material.

The diagram identifies three color-coded categories of hazard for each material:

Each category is divided in five levels of hazard potential ranging from 0 – 4, with (0) used to indicate no special hazards and (4) for severe or extreme hazard potential.

The degrees of hazard in each of these categories are given as follows:

Health – The degree of health hazard of a chemical or material is based on the form or condition of the material, and its inherent properties. The degree of health hazard of a material should indicate the degree of personal protective equipment required for working safety with the material:

- A rating of 1 is for slightly hazardous or toxic material which requires only minimal protection (e.g. safety glasses and gloves) in addition to normal work clothing.

- A rating of 2 is for moderately toxic or hazardous material which requires additional PPE or equipment (e.g. chemical goggles, lab/work smock, and local ventilation) in addition to that required for less toxic material. Consult the SDS for specific health hazard and proper PPE to use with this material.

- A rating of 3 or 4 is for highly to extremely toxic material and any carcinogen, mutagen, or teratogen. These materials will require specialized equipment (e.g. respirator or exhaust hood, full face shield, rubber apron, specialized glove, or handling tongs) beyond that required for moderately toxic material. The SDS and any other safety information must be consulted to determine the hazard and the proper PPE and engineering controls to safely use this material.

Flammability – The flammability hazards deal with the degree of susceptibility of the material to ignite and burn. The form or condition of the materials, as well as their properties, affects the extent of the hazard. Many hazardous materials such as acetone and gasoline have a flash point, far below freezing and will readily ignite with a spark if the vapor concentration is sufficient. A low rating of 1 is for material with a flash point above 200F, while more hazardous ratings of 2, 3, and 4 are for materials with respective flash point below 200, 100 and 73 F.

Reactivity – The reactivity hazards deal with the potential of a material or chemical to release energy. Some materials are capable of rapid release of energy without any catalyst, while others can undergo violent eruptive or explosive reactions if they come in contact with water or other materials. Generally this rating is used to indicate the potential to react if the material is heated, jarred, or shocked. A low rating of 1 indicates a material that is normally stable but may be reactive if heated. The more hazardous ratings of 2, 3, and 4 indicate a material is capable of violent reaction, shock/rapid heating and detonation respectively.

Other Hazard Information – An open space at the bottom of the NFPA diagram can be used to indicate additional information about the chemical or material. This information may include the chemical or material’s radioactivity, proper fire extinguishing agent, skin hazard, its use in pressurized containers, protective equipment required, or unusual reactivity with water. For example, the usual signal to indicate reactivity with water is this symbol “W”. Similarly, the words ACID, COR (corrosive), RAD (radiation), OXY (oxidizer), Rad (radioactive), CARC (carcinogen) or other abbreviations may be used.

Use the following link to download a PDF copy: NMSU Chemical Labeling Procedure

For detailed information regarding GHS Labeling please view this OSHA Brief.